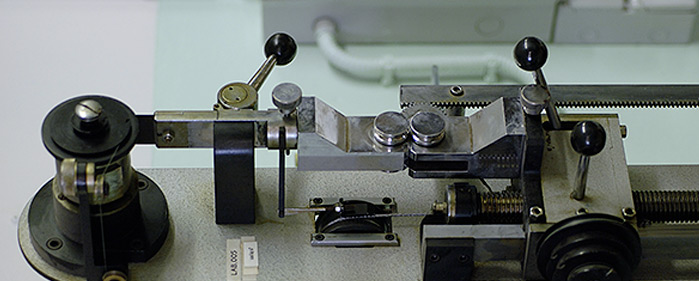

Checking and testing

Our research and development laboratory is equipped with cutting edge machinery that makes it possible to carry out checking and testing activities.

recovery rollers

Checking and testing activities for the roller coverings sector include:

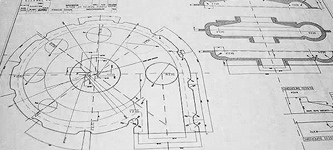

Checking size

This is carried out in accordance with specific internal working instructions and/or drawings supplied by the customer using measuring instruments that are correctly identified and subject to periodic calibration checks.

checking hardness

Hardness measurements are carried out using electronic or mechanical hardness testers that are correctly identified and subject to periodic calibration checks. Shore A and D scale measurements. Standard tolerance +/- 5 shore, close tolerance +/- 2 shore.

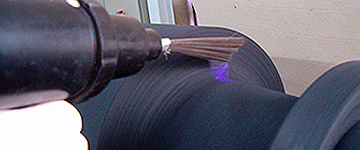

checking roughness

Some special processes require especially accurate surface finishes and only by checking with an electronic roughness tester ensures a correct evaluation of the degree of finish achieved.

checking balancing

Checking dynamic balancing and correcting any imbalances is not a standard check but is carried out on specific request of the customer.

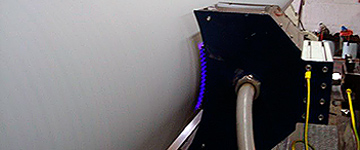

insulation test

A discharge of 15,000 Volts makes it possible to check the perfect electrical insulation of the coating. This test is carried out as standard on all rollers used for “corona treatment”.

scintilographic test

Often the coating has to protect the metal structure from the corrosive action of acid or highly corrosive baths: this test guarantees the water resistance of the coating especially in the critical join areas between the covered shell, the heads and collar.

rubber compounds

- Studying and developing tailor-made compounds to suit our customers’ needs;

- Constant monitoring by qualified technicians to carry out all the tests required by the UNI EN ISO 9001:2008 certification;

- Determining the physical-mechanical characteristics of our products;

- Chemical-physical resistance tests;

- Working with external laboratories to obtain compound certifications for various product sectors;

- Issuing technical documentation.

technical articles

Technical articles are constantly checked by:

- Visual and dimensional inspection of compliance with the relative drawings or samples

- Checking hardness

- Issuing certificate of conformity